Meltblown Filter Media

Meltblown Filter Media have extended application including filtering media for air and liquid, insulation, oil absorption, wipe cloth, and etc. While in air filtration, particularly in response to evolving energy consumption concerns, quality meltblown filter media are becoming an important role to supporting more sustainable, cost-effective HVAC operation.

Used across multiple industries — including air and liquid filtration, thermal insulation, oil absorption, and wiping cloths — due to its adaptable structure.

Its ultra-fine fiber structure makes it ideal for capturing fine particles in HVAC systems, ensuring cleaner air quality.

Supports sustainable and cost-effective HVAC operation by reducing energy consumption while maintaining high filtration performance.

Despite being lightweight, meltblown fabric offers excellent durability and reliability in industrial and commercial filtration setups.

Finer Meltblown Fibers Technology

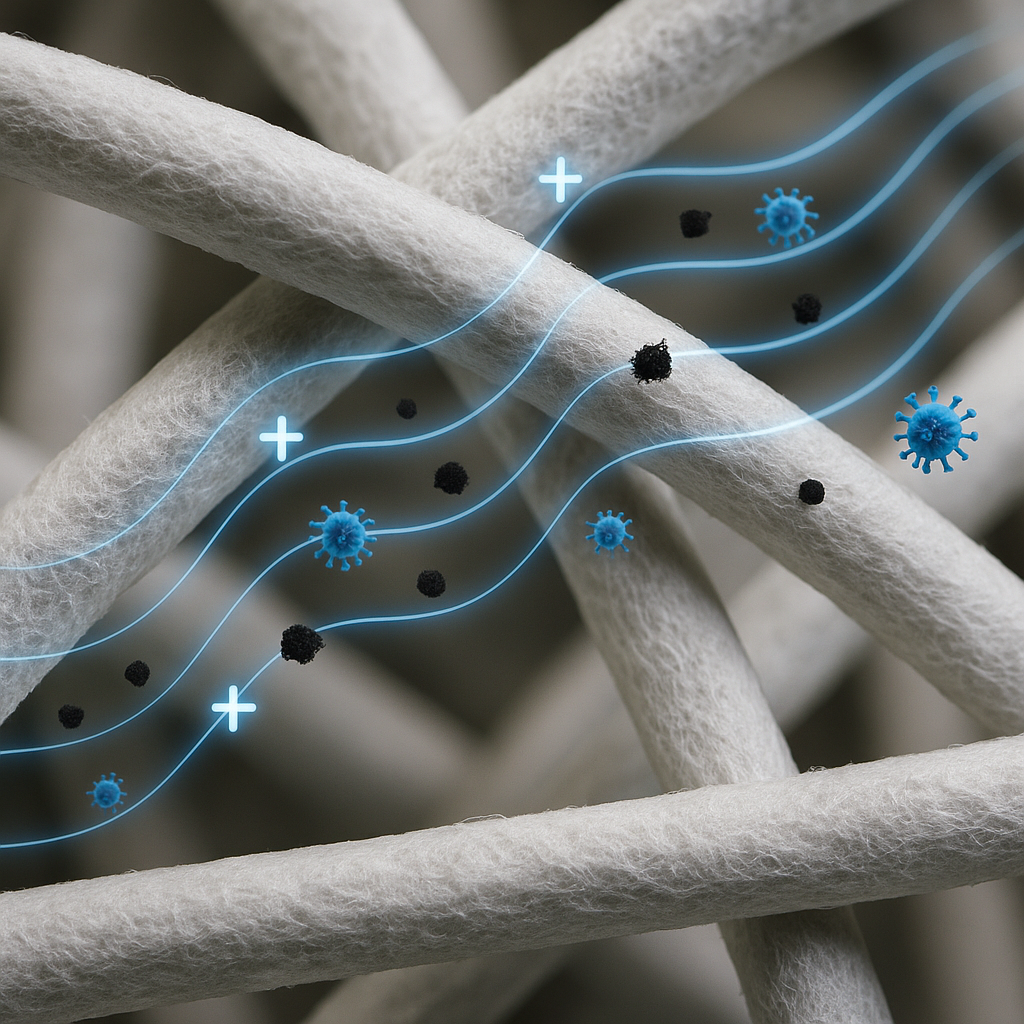

Produce filter media with smaller fiber diameter to improve the filtration efficiency and reduce the pressure drop.

Spinneret or die plate is a critical component in the meltblown nonwoven fabric production process. For example, some advanced spinnerets have nozzle hole diameters as small as 0.10 mm, with a hole density exceeding 100 holes per inch. The length-to-diameter (L/D) ratio of the nozzle holes can be greater than 35, and the melt pressure can reach up to 10.4 MPa, which facilitates the production of ultra-fine meltblown fibers.

Electret Media Charging Technology

The filtration efficiency of electret media have been proved to be remarkably higher than uncharged media and hence be an excellent fiber filtration material.

There are numerous electret media charging technologies. The common technique are corona charging, hydrocharging and thermal charging.

Under certain process temperatures and humidity conditions, corona charging allows charges to migrate from “shallow traps” to “deep traps”, resulting in more stable charge storage. Temperature affects the charge mobility and the fiber charge density within the electret filter media.

Polymer Modification Technology

Want to test our technology?

Experience the power of our nanofiber technology for yourself.

Request a free sample today and see how our materials can enhance your product’s performance.